Manchester Airport Terminal 2 and Pier 2

Full turnkey solution

Full turnkey solution

Team collaboration

Team collaboration

Sustainable strategy

Sustainable strategy

Deployment at live airport

Deployment at live airport

POWERING MANCHESTER AIRPORT’S TRANSFORMATION

We are proud to have delivered the mechanical and electrical works for Manchester Airport Terminal 2 and Pier 2, marking a significant milestone in Manchester Airport Group’s £1.3bn transformation programme.

A critical economic driver for the Northern Powerhouse, this investment has transformed Terminal 2 into a modern super‑terminal. The refurbishment includes the installation of 10 additional lanes of state‑of‑the‑art security scanning equipment, new international departure lounges, expanded retail areas, and upgraded operational spaces – all designed to deliver an enhanced passenger experience across both departures and arrivals.

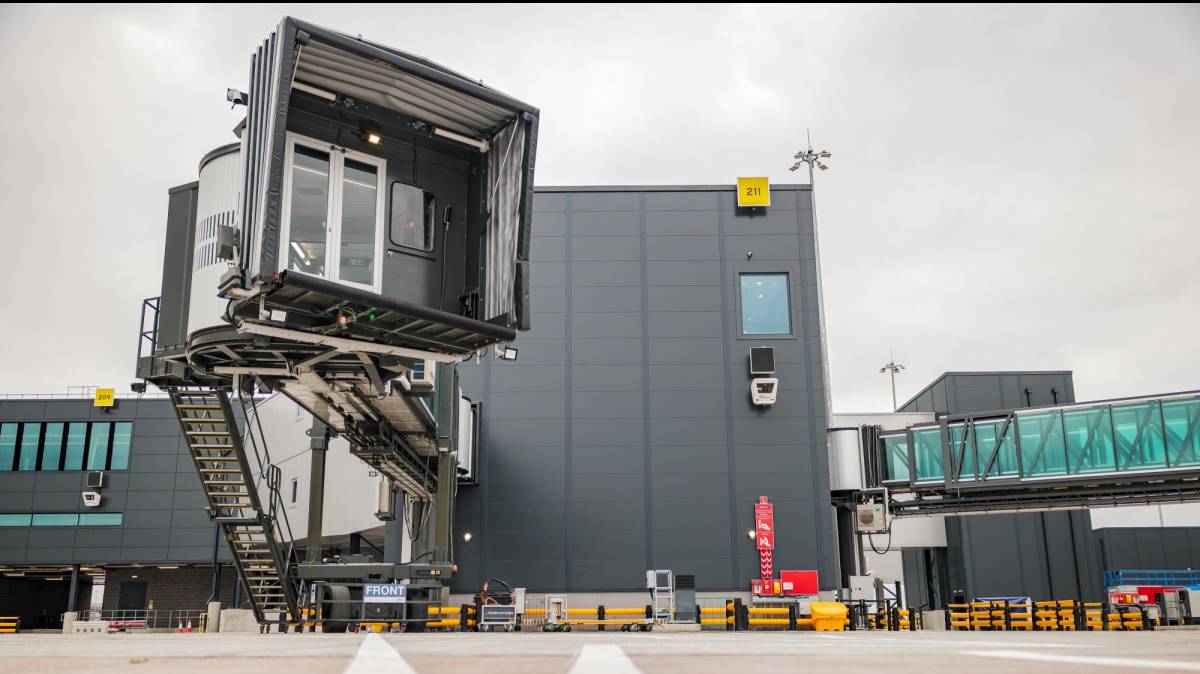

The addition of Pier 2, a modern boarding pier, will unlock the full capacity of Manchester’s dual runways and supported the airport’s continued growth, enabling new routes such as Islamabad and Delhi.

Pier 2 features 13 flexible aircraft stands, direct boarding access to all gates, a dedicated airline lounge, and retail space. It can accommodate large long-haul aircraft, including the A380, offering passengers a modern, spacious, and seamless travel experience.

By utilising DfMA solutions via our off-site manufacturing facilities, our involvement in this project not only enhances operational efficiency but also prioritises environmental sustainability, helping to reduce the development’s carbon footprint.

A project of this scale - the size of eight football pitches and involving over 600 people, either direct or part of our supply chain, working on a live site - was not without its challenges.

We successfully met all client project milestones as we progressively handed over areas to become operational, supporting MAG’s increasing capacity over the summer and winter holiday seasons.

Our Offsite Manufacture (OSM) team played a pivotal role in the project’s success, designing, manufacturing, and installing multi service horizontal modules, valve sets and fully serviced walk-in vertical risers including modular distribution boards which are part of our standard product range. Their involvement removed a significant proportion of hours of work from site and helping maintain the project safety record of no reportable accidents with over 750,000 hours worked (AFR of 0.0).

Terminal 2 will eventually cater for around 75% of the airport’s passengers as most airlines move from Terminals 1 and 3. The state-of-the-art facilities have already earned the prestigious Prix Versailles award for architecture and design.